VirtualMDLab - Facilities

Hardware | Software

Software

VirtualMDLab counts on softwares listed as follows:

|

SolidWorksSolidWorks is useful for 2D and 3D drawing, part assembly modeling and surfacing. It allows to reference previous parts while creating complex designs and stylish, continuous surfaces. (SolidWorks) |

RapidFormRapidForm is useful for handling point cloud, 3D scan data processing, mesh optimization and curve/surface modeling, among some other engineering functionalities for designing and developing industry products. (RapidForm) |

|

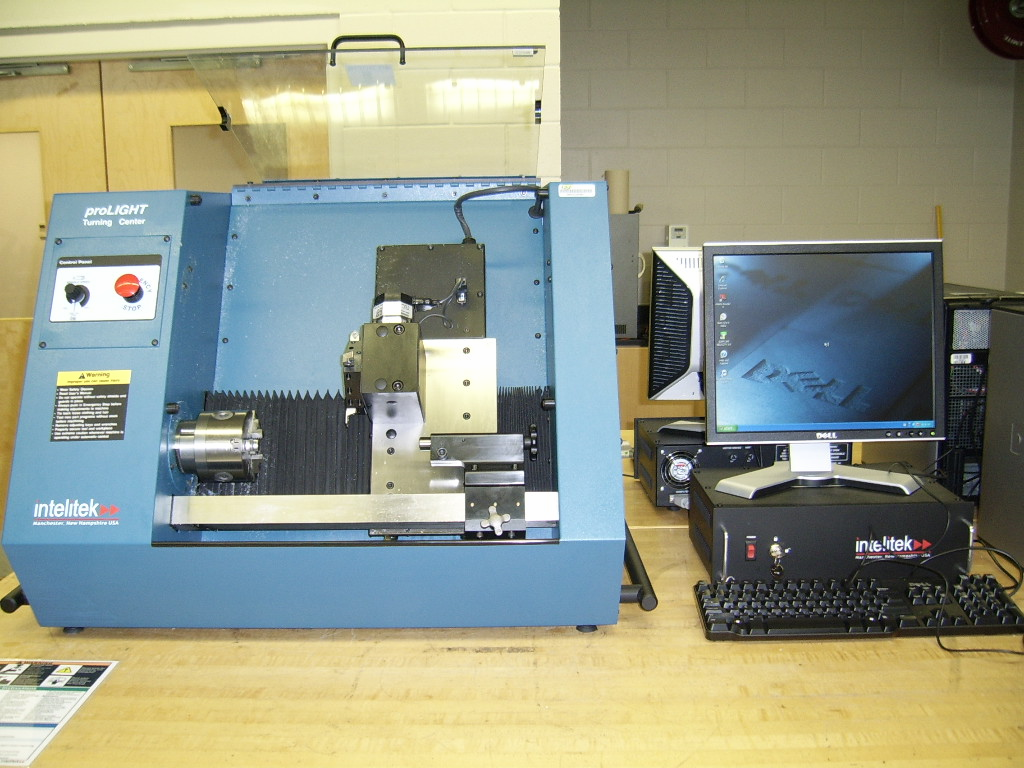

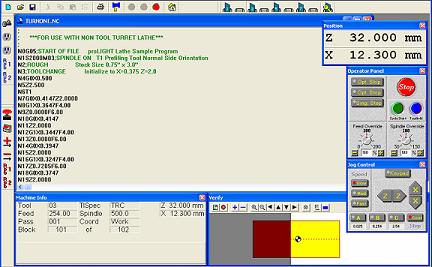

CNC proLight 3000CNC proLight 3000 allows the edition of programs, machine set up, cutting tool selection, tool path simulation and machining center operation. It features an intuitive interface and allows to use industrial EIA, ISO, Fanuc, G and M code standards. (Intelitek) |

|

CNCBaseCNCBase provides an intuitive tool for programming, operating and controlling the eXpertMill VMC-0600. The software accepts standard Fanuc-compatible EIA RS274D G an M codes. (Intelitek) |

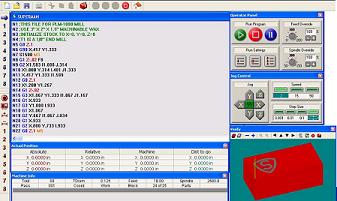

SURFCAM Velocity v3SURFCAM Velocity v3 is used for CNC programming of 2 to 5-axis milling centers, lathes and multi-tasking machines. SURFCAM’s toolpaths are highly automated. Useful for generating a complex, detailed and efficient toolpath, in seconds. (Surfware) |

Catalyst EXCatalyst EX controls the fused deposition modeling (FDM) machine by generating the deposition path needed for creating the model and generates support structures for building the model with ABS plastic. (Dimension) |

|

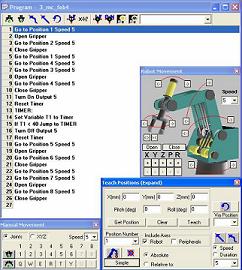

SCORBASESCORBASE creates the bridge that allows the comunication with the robot controller over USB channel. This software controls and displays in real-time the status of robot axes, gripper and peripheral devices; eight digital inputs, eight digital outputs, two analog outputs and four analog inputs. (Intelitek) |

|

RSLogix 500RSLogix 500 allows to program PLC within an industrial environment, modeling production processes, automation controls and setup process for equipment, among some other functions. (Rockwell Automation) |

|

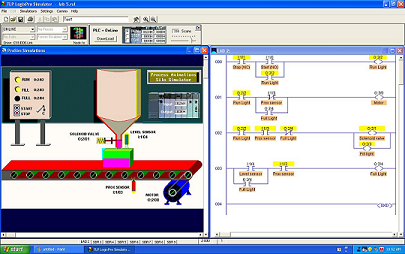

LogixPro 500LogixPro 500 is a tool for learning the fundamentals of ladder logic programming. By graphically simulating process equipment such as conveyors, flowmeters, pumps (and so on), it presents the synchronous and interactive nature of real industrial processes with a more realistic and challenging programming experience. (TheLearningPit) |