VirtualMDLab - Facilities

Hardware | Software

Hardware

The VirtualMDLab's modern design and manufacturing facilities include:

|

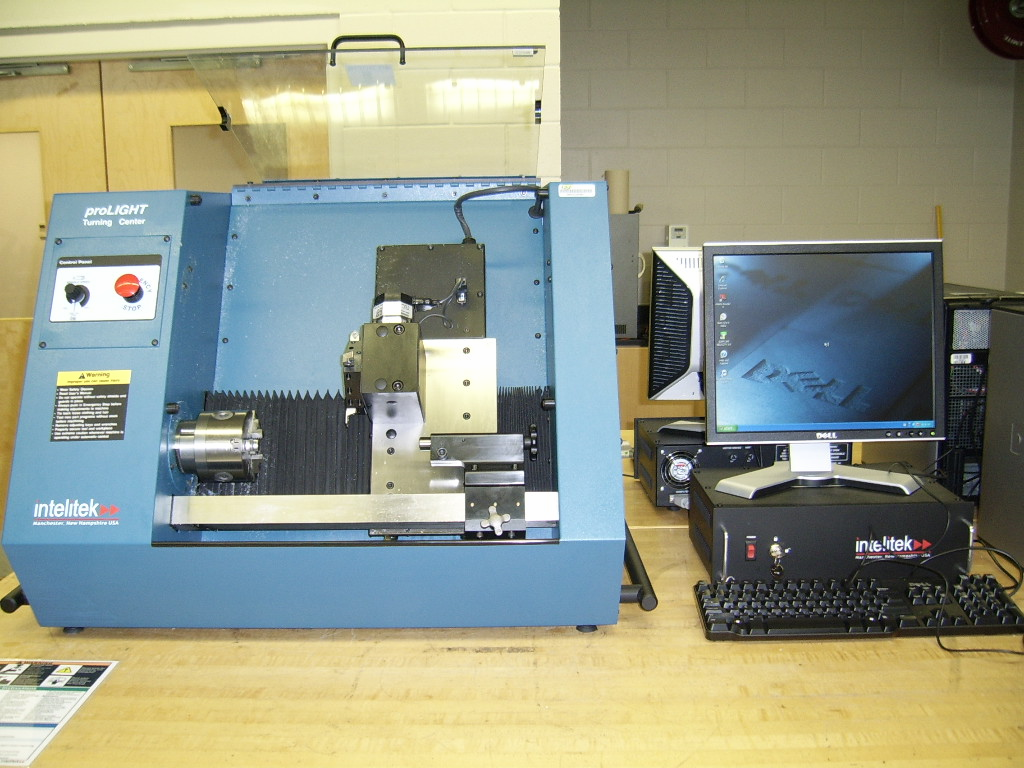

Turning CenterThis CNC proLIGHT 3000 Turning Center performs the machining process in which a single-point tool removes material from the surface of a cylindrical workpiece, feeding the tool linearly in a direction parallel to the axis of rotation. (Intelitek) |

|

Milling CenterThe CNC eXpertMill VMC-0600 performs the machining operation in which a workpart is fed using a rotating cylindrical tool with multiple cutting edges. The axis of rotation of the cutting tool is perpendicular to the direction of feed. (Intelitek) |

|

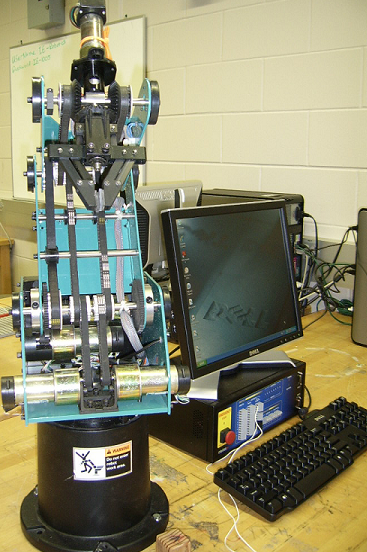

Training RobotCharacteristics of this SCORBOT-ER 4u robot, such as speed and repeatability, make it highly useful for stand-alone operations and integrated use in automated workcell applications such as robotic welding, machine vision, CNC machine tending and Flexible Manufacturing System operations. (Intelitek) |

|

Rapid Prototyping machineThe Dimension sst 768 uses ABSplus™plastic for producing robust component parts that can be snapped, screwed and fitted together. This printer models from the buttom up, one layer at a time. Once the STL file has been imported to the Catalyst®, this software automatically slices and orients the parts and creates support structures. The ABS plastic is melted, fed into an extrusion head, and properly deposited in layers as fine as 0.007 inches thick. (Dimension) |

|

3D PrinterThe ZPrinter® 450 uses powder, binder and ink cartridges for creating 3D models emerging from the bottom up one cross-section at a time. A vacuum and vibration system automatically removes up to 80% of loose powder and recycles it. Lightly compressed air is used in a fully enclosed chamber to remove the remaining powder. Then, models are then infiltrated to increase their strength. (ZCorporation) |